The term "diversity and inclusion" has been garnering attention in a wide variety of contexts in recent times. This term expresses the idea of organizations bringing together people of diverse backgrounds and value outlooks arising from differences in gender, nationality, ability, age, and other attributes, and enabling each one of them to use their capabilities to the fullest extent possible. What is required to create a workplace in which everyone finds it easy to work and participate actively? We seek answers to this question by examining the improvement activities underway on the production floor in OMRON Taiyo, a company where the majority of the employees have a disability.

OMRON Taiyo established Japan's first welfare-oriented factory back in 1972. With the exception of some short period, it has been operating at a profit ever since. OMRON Taiyo has fostered a culture in which each and every employee contributes their own ingenuity to collective improvement efforts aimed at creating a workplace where everybody feels comfortable, regardless of whether or not they have a disability.

Hirofumi Hikishio continually looks for ways to improve his workplace. Mr. Hikishio, who himself lives with a disability affecting his legs, joined the company in 1984, and has worked in a variety of areas including production, technical development, and quality control. Since 2018 he has been a team leader on the production line. He pursued improvement activities on a day-to-day basis, thoroughly inspecting the line from a variety of standpoints to identify difficult and wasteful tasks and ensure that everybody can perform their work safely and with ease. One day as Mr. Hikishio was doing his usual rounds, he found that there was a shortage of shrinkable tubing, one of the components used in products. To prepare this component it is necessary to cut a single long piece of tubing into specified lengths. He found one worker who was free and asked the worker to do the cutting, only to be told that the worker couldn't handle the cutter blade. Only a specific number of workers was permitted to take on this task, because handling the cutter blade was considered hazardous. Other workers had resigned themselves to being unable to perform the task themselves.

Mr. Hikishio, Production Line Team Leader

Mr. Hikishio, Production Line Team Leader

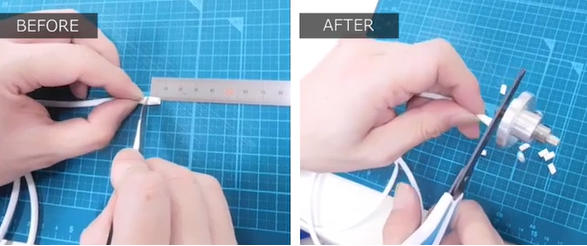

Mr. Hikishio hit upon the idea of producing a jig that would enable anyone to perform the task safely and easily. Conversations with three co-workers on the production line revealed that apart from the dangers involved in using the cutter blade, the task was made more difficult by the need to measure the lengths of tubing each time when cutting. Mr. Hikishio designed a jig that would solve this problem as well and tested his design repeatedly.

Working Hard on Improvements

Working Hard on Improvements

Finally, he succeeded in creating a universal process that any worker could perform. The cutter blade was replaced with ordinary scissors, and a guide was fitted to enable the expandable tubing to be cut in uniform lengths. Users simply needed to run the tubing along the guide in order to perform the cut: a task that could be performed by anybody, regardless of whether or not they had a disability, and by right-handers and left-handers alike. A task that previously had taken some workers up to 40 seconds to perform was reduced to just two seconds.

Procedures Before and After Improvement

Procedures Before and After Improvement

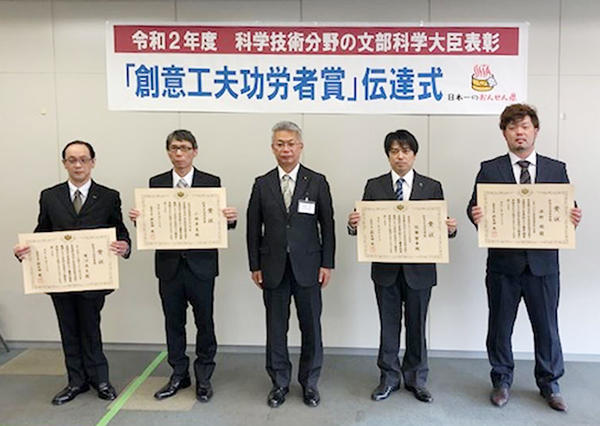

This innovation, which yielded an overall efficiency gain of 190 hours per year as well as improving quality and safety, received The Award for Creativity, commendation for science and technology by the Minister of Education, Culture, Sports, Science and Technology* in 2020.

Award Ceremony (Mr. Hikishio Far Left)

Award Ceremony (Mr. Hikishio Far Left)

Mr. Hikishio says: "The jig I created seems to have made my co-workers delighted at being able to perform the task more easily and having their range of work expanded. It makes me very happy to see this and to watch them engaging so enthusiastically in their work, and I'm now inspired to create something even better. I would like to continue making improvements one by one, to help my co-workers fulfil their potential."

Another person from the same workplace offered the following comment on Mr. Hikishio's innovation.

"Mr. Hikishio is a busybody [laughs]. He's always walking around the production line, and whenever he finds a worker who seems to be struggling, he immediately talks to them and looks for ways to improve. He works from day to day to make improvements that create a better workplace for everybody."

Mr. Hikishio is just one of the many employees of OMRON Taiyo who use their own ingenuity to formulate and propose improvements routinely. Improvement proposals numbered 174 in the 2019 fiscal year alone and have totaled 1,263 in the nine years since 2011.

As each individual acts and pursues improvements with their fellow workers in mind, they create a comfortable workplace where everybody can participate actively. The efforts of each and every employee to put "diversity and inclusion" into practice are what make OMRON Taiyo the company that it is today.

Group Photograph of the Employees of OMRON Taiyo

*About the Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology

The Minister of Education, Culture, Sports, Science and Technology operates a program of Minister's Awards for the purposes of acknowledging the meritorious work of individuals with notable achievements in research, development, promotion of understanding and the like in the field of science and technology and helping to raise the standards of science and technology in Japan.